Water-cooled alternators serve as the backbone of reliable power generation in extreme environments, delivering consistent electrical output where traditional air-cooled systems fail. Understanding why engineers consistently choose water-cooled technology over alternatives reveals the engineering excellence that makes dependable power generation possible in high-temperature and offshore conditions.

[Engineering analysis reveals critical advantages:]

Water-cooled alternators transfer heat 40 times more effectively than air-cooled units, maintaining optimal operating temperatures

Advanced cooling systems resist corrosion and contamination for 25+ years in harsh environments

Superior thermal management allows continuous operation at ambient temperatures up to 60°C

Natural cooling efficiency maintains consistent power output without thermal derating

Marine-grade designs prevent salt corrosion that damages conventional alternators

Compact installation footprint maximizes power density for space-constrained applications

Every industrial facility operating in extreme conditions depends on water-cooled alternators to maintain reliable power generation while delivering the durability and performance that critical operations demand.

Key Takeaways

• Water-cooled alternators provide superior thermal management through liquid cooling circuits that maintain optimal operating temperatures under extreme conditions

• Enhanced heat dissipation prevents thermal derating and maintains rated power output at ambient temperatures up to 60°C where air-cooled units fail

• Marine-rated designs resist salt corrosion and environmental contamination that compromise conventional alternator performance

• Compact cooling systems enable higher power density installations in space-constrained offshore and industrial environments

• Extended service life reduces maintenance costs and improves system reliability in remote or difficult-access locations

• Thermal stability ensures consistent voltage regulation and power quality under varying load conditions

• Professional installation creates permanent cooling circuits that operate reliably for decades without performance degradation

• Environmental adaptability includes resistance to humidity, salt spray, and extreme temperature fluctuations

What Makes Water-Cooled Alternators Essential for Extreme Conditions?

The Science of Advanced Thermal Management

Water-cooled alternators excel in extreme environments due to superior heat transfer properties and thermal management capabilities. With heat transfer coefficients 40 times higher than air cooling, liquid cooling systems effectively remove heat generated during power conversion even under the most demanding conditions. This superior cooling enables continuous operation at full rated power when ambient temperatures reach 60°C.

The closed-loop cooling system circulates coolant through strategically placed channels within the alternator housing. Heat generated by windings and magnetic components transfers rapidly to the circulating coolant, which carries thermal energy to external heat exchangers for dissipation. This process maintains critical component temperatures within optimal ranges regardless of ambient conditions.

Note: Thermal management directly impacts alternator lifespan and reliability. Water-cooled alternators with superior cooling systems operate 25-40% longer than air-cooled alternatives in extreme environments while maintaining consistent performance throughout their service life.

| Cooling Method | Heat Transfer Rate | Max Ambient Temp | Power Derating |

Water-Cooled | Excellent | 60°C | None |

Air-Cooled | Limited | 40°C | 20-30% |

Forced Air | Moderate | 45°C | 10-15% |

Why Water Cooling Outperforms Alternatives

Water-cooled alternators require cooling systems that combine superior heat transfer with mechanical reliability and environmental resistance. Liquid cooling delivers this unique combination better than any alternative method. Air-cooled systems struggle under high ambient temperatures and require thermal derating that reduces available power. Forced air cooling improves performance but remains limited by air's inferior thermal properties.

Water's thermal properties enable both excellent heat transfer and consistent cooling performance across temperature extremes. The cooling system maintains its effectiveness regardless of ambient conditions while providing protection from environmental contaminants that affect air-cooled systems. This consistency ensures water-cooled alternators perform reliably throughout decades of operation in challenging environments.

Extreme Environment Requirements

Industrial and offshore applications demand alternators that maintain stable operation when exposed to extreme temperatures, humidity, salt spray, and contamination. Water-cooled alternators demonstrate complete environmental compatibility through sealed cooling systems that protect internal components from harsh conditions. This environmental isolation prevents performance degradation that affects conventional alternators in extreme conditions.

The sealed cooling circuit design minimizes contamination entry points while maintaining optimal internal conditions regardless of external environment. These characteristics ensure reliable operation and extend component life in applications where environmental protection cannot be compromised.

Importance in High-Temperature and Offshore Applications

Thermal Performance Advantages

Water-cooled alternators enable maximum power output through superior thermal management that prevents heat-related derating. The advanced cooling systems maintain component temperatures within optimal ranges while using minimal energy for cooling operation. Systems with properly designed liquid cooling typically deliver 15-25% higher continuous power ratings compared to air-cooled alternatives in extreme conditions.

Efficient thermal management also enables more compact alternator designs without sacrificing power output. Water-cooled alternators achieve higher power density through effective heat removal, allowing manufacturers to reduce overall system size while maintaining electrical capacity. This efficiency translates to reduced installation space requirements and improved system integration.

System Reliability and Environmental Resistance

The sealed design of water-cooled alternators ensures reliable operation under the pressure variations and environmental extremes inherent in offshore and high-temperature applications. The cooling system's corrosion resistance prevents degradation from salt spray, humidity, and chemical contaminants, while thermal stability accommodates extreme temperature cycling without performance loss.

Safety benefits include the system's ability to maintain safe operating temperatures even during emergency conditions or cooling system disruptions. Unlike air-cooled systems that may overheat rapidly, water-cooled alternators provide thermal inertia that allows controlled shutdown procedures when necessary.

Long-term Performance Value

Water-cooled alternators deliver exceptional value through extended service life and minimal maintenance requirements in extreme environments. Properly designed liquid cooling systems typically operate efficiently for 25-30 years without major maintenance, far exceeding the lifespan of air-cooled alternatives in similar conditions. This longevity reduces lifecycle costs while providing consistent power generation throughout the system's operational life.

The environmental protection provided by sealed cooling systems maintains internal component cleanliness and performance without requiring frequent maintenance or component replacement. This reliability proves especially valuable in remote offshore installations where maintenance access requires significant time and expense.

Tip: Quality water-cooled alternators with professional installation create power systems that deliver reliable electrical generation with minimal maintenance for decades of operation in extreme environments.

How Water-Cooled Alternators Work in Extreme Conditions

Thermal Management Integration

Water-cooled alternators enable consistent power generation by effectively removing heat generated during electrical conversion. Coolant circulates through internal passages adjacent to heat-generating components, absorbing thermal energy as it flows through the alternator. The heated coolant then flows to external heat exchangers where thermal energy transfers to ambient air or seawater.

The cooling circuit maintains optimal component temperatures by continuously circulating coolant at controlled flow rates and temperatures. This thermal management prevents hot spots that could damage windings or magnetic components while ensuring consistent electrical performance under varying load conditions.

Heat Exchange Optimization

The thermal design of water-cooled alternators maximizes heat transfer efficiency through optimized coolant passages and heat exchanger configurations. Internal cooling channels position coolant flow adjacent to primary heat sources, enabling rapid thermal transfer from critical components to circulating coolant. This efficient design maintains component temperatures well below maximum ratings even under full load operation.

External heat exchangers optimize thermal rejection to ambient conditions through enhanced surface area and airflow design. The superior heat transfer ensures efficient cooling even under high ambient temperatures, maintaining alternator capacity and preventing thermal shutdowns that affect air-cooled systems.

Environmental Protection Systems

Water-cooled alternators must maintain cooling system integrity throughout operation in extreme environments. The sealed cooling system design protects internal components from salt spray, humidity, and contaminants while maintaining coolant quality and system pressure. Proper system design ensures adequate coolant circulation under varying conditions without compromising cooling effectiveness.

The cooling system's environmental sealing prevents contamination entry while enabling thermal expansion accommodation and system serviceability. This mechanical stability maintains cooling system integrity while enabling reliable alternator operation under extreme environmental conditions.

Note: Optimal cooling system design and installation practices ensure water-cooled alternators deliver maximum thermal management efficiency while maintaining environmental protection and system reliability.

Types and Manufacturing

Cooling System Configurations

Water-cooled alternators utilize specific cooling system designs optimized for extreme environment applications. Marine-grade systems feature corrosion-resistant materials and enhanced sealing that withstand salt spray and humidity exposure. Industrial configurations incorporate robust heat exchangers and filtration systems that maintain cooling effectiveness despite contaminated ambient conditions.

Cooling system materials include marine-grade alloys and protective coatings that resist environmental degradation while maintaining thermal transfer efficiency. The resulting systems maintain consistent cooling performance throughout extended service life while resisting damage from harsh operating environments.

Power Ratings and Sizing

Water-cooled alternators are available in power ratings from 50 kW to 5000+ kW with cooling systems sized to maintain optimal performance across the full power range. Proper sizing considers heat generation rates, ambient conditions, and cooling system capacity to optimize performance while maintaining adequate thermal safety margins.

| Application Type | Power Range | Cooling Capacity |

Marine Systems | 100-2000 kW | 150-300 kW thermal |

Industrial Plants | 500-5000 kW | 750-7500 kW thermal |

Offshore Platforms | 1000-3000 kW | 1500-4500 kW thermal |

Professional sizing calculations consider electrical load requirements, environmental conditions, and installation constraints to optimize alternator selection while ensuring reliable cooling performance.

Environmental Protection Integration

Marine-grade water-cooled alternators combine alternator assemblies with specialized environmental protection systems that prevent corrosion and contamination damage. The protection systems maintain consistent internal conditions around electrical components while providing moisture resistance and thermal insulation. Complete environmental sealing options reduce installation complexity while ensuring uniform protection quality.

Corrosion-resistant coatings and materials offer superior environmental protection compared to standard alternatives. The protective systems prevent salt and contaminant penetration that could reduce electrical performance or accelerate component degradation. Protection effectiveness varies based on alternator size, operating environment, and installation requirements.

Performance Benefits

Power Output Reliability

Water-cooled alternators significantly improve power generation reliability through superior thermal management that prevents heat-related failures. The advanced cooling enables alternators to maintain full rated power output under extreme conditions while using efficient thermal management. Systems with quality liquid cooling typically achieve 20-30% higher availability compared to those using air-cooled alternatives in extreme environments.

Consistent power output eliminates the thermal derating that reduces available power from air-cooled systems during high ambient temperature operation. The reliable performance often provides substantial operational benefits that exceed the initial cooling system investment within the first few years of operation.

Environmental Durability

Properly designed water-cooled alternators require minimal maintenance while delivering consistent performance for decades in extreme environments. The environmental protection prevents degradation from salt spray, humidity, and chemical contaminants that affect conventional alternators. This durability eliminates frequent alternator replacement and reduces system downtime in critical applications.

The sealed cooling system design prevents contamination accumulation that could affect electrical performance or accelerate component wear. Natural environmental isolation maintains alternator cleanliness without requiring specialized maintenance procedures or environmental controls.

Installation Advantages

Professional power system engineers prefer water-cooled alternators for extreme environment applications due to superior environmental protection and thermal management capabilities. The systems accommodate complex installations without compromising electrical performance or cooling effectiveness. This reliability reduces installation complexity and enables optimal power system layouts.

Advanced cooling system connections create permanent, leak-proof installations that maintain effectiveness under thermal cycling and environmental exposure. The compatibility between cooling systems and standard power system components ensures reliable installations that perform throughout the alternator's service life.

Tip: Quality water-cooled alternators combined with professional installation techniques deliver optimal power generation performance with minimal maintenance requirements in extreme environments.

Industry Standards and Certification

Marine and Industrial Standards

All marine-grade water-cooled alternators must meet specific standards for operation in extreme environments. These standards define environmental protection requirements, thermal performance criteria, and safety specifications that ensure reliable operation under harsh conditions.

Key requirements include environmental sealing effectiveness, cooling system reliability, and electrical performance under extreme temperature conditions. Compliance testing verifies that alternators meet durability and performance standards necessary for critical power generation applications.

Quality Assurance Standards

Manufacturing quality standards ensure water-cooled alternators deliver consistent performance and reliability in extreme environments. Certified facilities maintain process controls that guarantee thermal performance, environmental protection, and electrical output quality. Quality control systems monitor critical parameters throughout production to identify potential variations before they affect product reliability.

Testing protocols include thermal cycling, environmental exposure, and electrical performance verification that simulate decades of extreme environment operation. Only alternators meeting all performance criteria receive certification for critical power generation applications.

Performance Certification

Certified water-cooled alternators undergo comprehensive testing to verify performance under actual extreme operating conditions. Testing includes thermal cycling, salt spray exposure, and vibration resistance evaluation that simulate harsh industrial and marine service conditions. Regular facility audits ensure continued compliance with quality standards and certification requirements.

This ongoing oversight maintains product integrity and performance consistency across different production batches and operating environments.

Practical Applications

Offshore Platform Installation

Offshore oil and gas platforms utilize water-cooled alternators ranging from 1000-3000 kW capacity depending on platform power requirements and operational needs. The alternators provide primary electrical power while withstanding salt spray, humidity, and extreme temperature conditions throughout extended offshore deployment periods.

Professional installation includes proper cooling system integration, environmental sealing, and vibration isolation that protect alternators from platform motion and harsh marine conditions. Support systems and maintenance access enable reliable operation and serviceability despite remote installation locations.

Industrial Process Applications

High-temperature industrial facilities require water-cooled alternators to handle extreme ambient conditions and continuous operation requirements. Alternator capacities typically range from 500-5000 kW with cooling systems designed for specific industrial environments and heat rejection requirements.

Complex industrial installations require careful coordination of cooling systems, electrical distribution, and environmental protection systems. Water-cooled alternators in industrial applications often include specialized monitoring and control systems for integration with facility management systems.

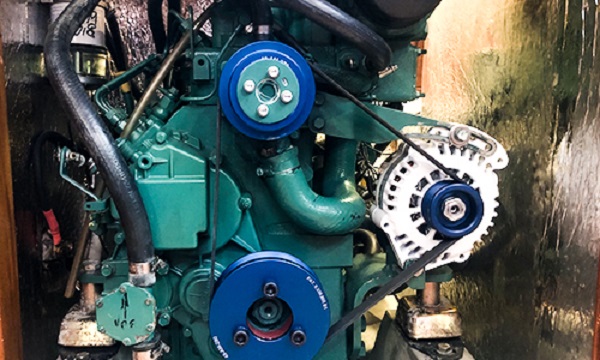

Marine Vessel Systems

Commercial and naval vessels utilize water-cooled alternators designed for marine environment operation and space-constrained installations. These systems must provide reliable power generation while withstanding ship motion, salt spray, and limited maintenance access during extended voyages.

Critical marine applications including research vessels, offshore supply ships, and naval platforms demand the highest reliability and performance from power generation systems. The proven performance of water-cooled alternators in demanding marine environments makes them the preferred choice for mission-critical vessel power systems.

Conclusion: Engineering Excellence for Extreme Environments

Water-cooled alternators represent the optimal engineering solution for power generation systems operating in high-temperature and offshore environments through their unique combination of thermal management efficiency, environmental protection, and operational reliability. These essential power components enable consistent electrical generation while delivering the durability and performance that extreme environment applications demand.

Professional selection and installation of quality water-cooled alternators ensures optimal power system performance, thermal efficiency, and operational reliability throughout decades of service in challenging conditions. The superior capabilities of water-cooled technology continue to make it the preferred choice for demanding applications where power generation reliability cannot be compromised.

For facility managers and marine operators seeking reliable power generation solutions for extreme environments, partnering with experienced OEM auto parts suppliers ensures access to quality alternators that meet stringent performance requirements. When selecting alternator suppliers for demanding applications, consider manufacturers like ELECDURA that understand the critical role advanced cooling plays in power system performance and provide the technical expertise necessary for successful extreme environment installations.

FAQ

Why do extreme environment applications specifically use water-cooled alternators instead of air-cooled systems?

Water-cooled alternators provide superior thermal management, environmental protection, and consistent power output under conditions where air-cooled systems experience thermal derating or failure. The liquid cooling maintains full rated power at ambient temperatures up to 60°C.

What happens if water-cooled alternator cooling systems are undersized?

Undersized cooling systems create excessive component temperatures that reduce alternator efficiency and accelerate wear. The system must operate at reduced power levels to prevent overheating, leading to decreased electrical capacity and potential component damage.

How long do water-cooled alternators typically last in extreme environments?

Properly designed water-cooled alternators typically operate efficiently for 25-30 years with appropriate maintenance in extreme environments. Quality cooling systems and environmental protection can extend service life even further under proper operating conditions.

Can damaged water-cooled alternator cooling systems be repaired?

Minor cooling system issues can often be repaired through professional service techniques. However, extensive corrosion, seal failure, or heat exchanger damage typically requires system replacement to maintain alternator safety and performance.

What cooling system maintenance is required for water-cooled alternators?

Regular coolant analysis, heat exchanger cleaning, and seal inspection maintain cooling system effectiveness. Maintenance intervals depend on operating environment and coolant quality, typically ranging from annual to multi-year schedules.

Are there alternatives to water cooling for extreme environment alternators?

While alternatives exist, none match water cooling's combination of thermal management, environmental protection, and power density. Other cooling methods typically require performance compromises or increased maintenance in extreme conditions.