In the intricate ecosystem of a modern vehicle or industrial machine, the alternator stands as a silent sentinel of power. Its fundamental role—converting mechanical energy from the engine into electrical energy to power systems and recharge the battery—is well understood. However, as automotive and industrial technology has advanced, pushing towards higher efficiency, greater power density, and reduced emissions, the demands on this crucial component have skyrocketed. The traditional air-cooled alternator, with its characteristic fan blades and ribbed casing, began to reach its thermal limits. The answer to this challenge emerged in the form of a more sophisticated and efficient design: the water cooled alternator.

This article will dissect the inner workings of the water-cooled alternator, exploring its design principles, operational advantages, and the specific applications where it truly shines.

The Thermal Challenge: Why Air Cooling Reaches Its Limit

To understand the necessity of water cooling, one must first appreciate the thermal dynamics at play. An alternator is not a perfectly efficient device; a significant portion of the mechanical energy it consumes is lost as heat. These losses primarily occur in two areas:

Copper Losses (I²R Losses): As electric current flows through the copper windings of the stator (the stationary part), resistance causes heating. This heat generation is proportional to the square of the current (I²), meaning that a small increase in electrical output demands a massive increase in heat dissipation.

Iron Losses: The rapid magnetic field reversals in the alternator's core generate heat through hysteresis and eddy currents.

In a conventional air-cooled alternator, an internal fan mounted on the rotor shaft draws ambient air through the casing. This air flows over the stator windings and the internal rectifier bridge, carrying heat away to the environment. This method works adequately for standard applications but has critical drawbacks:

Inefficiency: Air is a poor conductor of heat compared to liquids. Its ability to absorb and transport thermal energy is limited.

Packaging Constraints: As engineers demanded more power from smaller units (a concept known as power density), the available surface area for ribbed cooling fins diminished.

Noise: The internal fan and the rushing air contribute significantly to the alternator's operational whine.

Dependency on Under-hood Temperature: The cooling efficiency is directly tied to the already hot and often dirty air within the engine bay.

When pushed to their limits, air-cooled alternators risk overheating. Excessive heat degrades the insulation on the windings, damages the diodes in the rectifier, and can ultimately lead to catastrophic failure. The water-cooled alternator was engineered specifically to overcome these thermal barriers.

The Core Principle: Liquid as a Superior Heat Conduit

The fundamental innovation of the water-cooled alternator is simple yet profound: it replaces the flow of air with the flow of liquid coolant. Water, or typically a water-glycol mixture identical to the engine coolant, is a far more effective medium for heat transfer. It has a thermal conductivity roughly 25 times greater than air and a specific heat capacity about four times higher. This means it can absorb vastly more heat energy for a given rise in temperature.

This superior heat-carrying capacity allows the alternator to be designed for higher continuous electrical output without increasing its physical size, or conversely, to be made significantly smaller and lighter for the same power rating.

Anatomy of a Water-Cooled Alternator: A Step-by-Step Breakdown

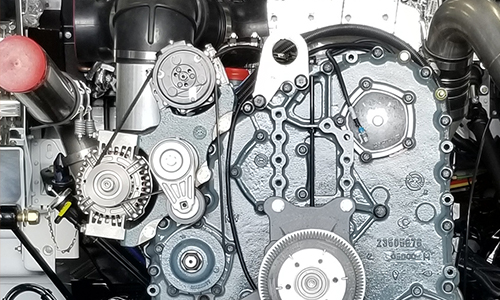

The design of a water-cooled unit is distinctly different from its air-cooled counterpart.

1. The Cooling Jacket:

The most prominent feature is the absence of external cooling fins. Instead, the alternator's front and rear housings are cast with an integral void that surrounds the stator assembly. This void, known as the cooling jacket, is a sealed passage through which engine coolant is circulated. The stator, which is the primary source of heat, is thus encased in a constantly flowing stream of coolant. This provides direct and immensely efficient cooling to the component that needs it most.

2. The Coolant Circuit:

The alternator is plumbed directly into the vehicle's existing engine cooling system. Small-diameter hoses connect the alternator's inlet and outlet ports to the engine's coolant loop. A dedicated electric coolant pump (often separate from the main engine water pump) may be used to ensure a consistent flow of coolant through the alternator, even at low engine speeds when the main pump's flow is reduced. The heated coolant exiting the alternator is then fed back to the engine's radiator, where it is cooled before recirculating.

3. The Stator and Rotor:

The core electrical components—the stator windings and the rotor (which contains the field winding and creates the rotating magnetic field)—are designed with materials that can withstand the more stable and lower operating temperatures enabled by liquid cooling. The rotor, while not directly cooled by the jacket, benefits from the overall cooler internal environment and often employs special designs to minimize heat generation.

4. The Rectifier and Brushless Design:

The rectifier bridge, which converts the alternator's AC output to DC, is another major heat source. In many water-cooled designs, this assembly is mounted directly against the cooling jacket, allowing its heat to be efficiently transferred to the liquid. Furthermore, most modern water-cooled alternators are brushless. By eliminating the brushes and slip rings—components that are prone to wear and generate friction and heat—the design becomes more reliable and efficient, further reducing internal thermal loads.

5. Sealing and Insulation:

A critical engineering challenge is ensuring the complete separation of the electrical components from the liquid coolant. The unit is meticulously sealed using high-quality gaskets and O-rings at all junctions. The stator windings are also impregnated with a special resin or varnish that provides exceptional electrical insulation and protects against any potential moisture ingress, guaranteeing integrity and safety.

The Multifaceted Advantages: More Than Just Cooling

The adoption of water-cooling delivers a suite of benefits that extend beyond mere temperature management:

Higher Power Density and Output: The primary advantage. These alternators can reliably produce significantly more current (often 150-250 amps, and much higher in industrial settings) in a much smaller and lighter package. This is crucial for modern vehicles laden with power-hungry features like advanced infotainment, heated seats and steering wheels, and numerous electronic control units (ECUs).

Enhanced Efficiency: By maintaining a lower and more consistent operating temperature, electrical resistance in the copper windings is reduced. Lower resistance means fewer I²R losses, translating into more of the engine's mechanical power being converted into usable electricity rather than wasted as heat. This contributes marginally to better fuel economy.

Reduced Noise: The elimination of the internal cooling fan results in a dramatically quieter operation. This is a critical feature for luxury vehicles where cabin noise, vibration, and harshness (NVH) are paramount.

Improved Reliability and Longevity: Stable, lower operating temperatures drastically reduce thermal stress on all components, particularly the insulation on the windings and the diodes in the rectifier. This leads to a significantly longer service life and reduced risk of failure.

Packaging Flexibility: Without the need for external fins to radiate heat, the alternator can be designed with a smooth, compact cylindrical shape. This allows engineers more freedom to mount it in tight under-hood spaces, even in locations with poor airflow.

Applications: Where Water-Cooled Alternators Excel

While the technology offers clear benefits, it is more complex and expensive than air-cooling. Therefore, its use is targeted at specific applications where its advantages are indispensable:

High-End Automotive: Luxury sedans and SUVs from manufacturers like Mercedes-Benz, BMW, and Audi, where high electrical demand meets a requirement for sublime quietness.

Commercial Vehicles: buses, long-haul trucks, and emergency vehicles that require immense electrical power for lighting, communications, and HVAC systems for extended periods.

Hybrid and Electric Vehicles: In hybrids, the alternator (often integrated into the hybrid system as a motor-generator) operates under extreme and variable loads, making efficient cooling essential. The smooth, compact profile also aids packaging within a complex drivetrain.

Marine and Industrial Machinery: Environments where dust, dirt, or moisture could clog the fins of an air-cooled unit, or where space is at a premium and reliability is non-negotiable.

Conclusion

The water-cooled alternator represents a significant evolution in automotive and industrial electrical systems. By harnessing the superior thermal properties of liquid coolant, it solves the fundamental limitations of air-cooled design. It is a masterpiece of engineering that delivers unparalleled power density, remarkable efficiency, whisper-quiet operation, and exceptional durability. As the electrification of vehicles continues to accelerate and the demand for electrical power grows inexorably, the water-cooled alternator is poised to become the standard, ensuring that the hidden powerhouse of the machine can keep up with the ever-increasing thirst for energy.